Views: 0 Author: Site Editor Publish Time: 2024-12-20 Origin: Site

The cosmetic industry's packaging sector has witnessed remarkable growth and innovation, particularly in the realm of empty lip gloss tubes. These seemingly simple containers represent a confluence of design, functionality, and manufacturing excellence that supports the burgeoning beauty industry. This comprehensive exploration delves into the various aspects of empty lip gloss tubes, examining their manufacturing processes, design considerations, and market implications.

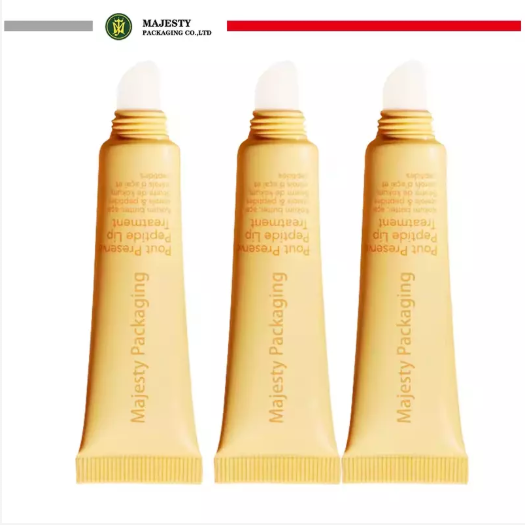

The evolution of lip gloss packaging has led to the development of sophisticated squeeze tubes that combine practicality with user-friendly design. These tubes represent a significant advancement in cosmetic packaging, offering several advantages over traditional container formats. The squeeze tube design allows for precise product dispensing, minimizing waste and ensuring optimal product usage.

Modern squeeze tubes incorporate various innovative features that enhance their functionality. The materials used typically include food-grade plastics that ensure product safety while maintaining flexibility for easy dispensing. The squeeze mechanism must be carefully calibrated to provide consistent product flow without excess force, making it accessible to all users while preventing product wastage.

The design considerations for squeeze tubes extend beyond basic functionality. Manufacturers must account for factors such as product viscosity, desired flow rate, and user experience. The tube's wall thickness plays a crucial role in maintaining structural integrity while remaining flexible enough for easy manipulation. Additionally, the orifice size and shape must be precisely engineered to ensure smooth product dispensing without clogging or excessive flow.

Manufacturing empty lip gloss tubes requires sophisticated equipment and stringent quality control measures. Modern manufacturers employ advanced injection molding and extrusion processes to create tubes that meet exact specifications while maintaining consistency across large production runs. The manufacturing process typically involves several stages, each crucial to the final product's quality and functionality.

The initial stage involves material selection, where manufacturers must choose appropriate plastics that meet both regulatory requirements and performance specifications. Common materials include LDPE (Low-Density Polyethylene), HDPE (High-Density Polyethylene), and various specialty polymers designed for cosmetic packaging. These materials must pass rigorous testing for chemical compatibility, durability, and safety.

Quality control in tube manufacturing involves multiple checkpoints throughout the production process. Manufacturers must verify dimensions, wall thickness consistency, seal integrity, and surface finish quality. Advanced testing equipment, including precision measuring devices and leak detection systems, ensures that each batch meets specified standards. This attention to detail is crucial for maintaining product quality and brand reputation.

Manufacturers must also consider environmental factors in their production processes. Many are now implementing sustainable practices and exploring eco-friendly materials in response to growing consumer demand for environmentally responsible packaging. This includes developing biodegradable options and increasing the use of recycled materials in tube production.

Clear lip gloss tubes have become increasingly popular due to their aesthetic appeal and practical benefits. The transparency allows consumers to easily monitor product levels and verify the contents' condition. This visual access creates a sense of trust and enables better product management for end-users.

The design of clear tubes presents unique challenges in manufacturing. The material must maintain clarity while meeting structural requirements and regulatory standards. Manufacturers often use specialized polymers that combine transparency with durability, ensuring the packaging remains attractive throughout its service life.

Marketing professionals recognize the value of clear packaging in product presentation. The visibility of the product can enhance shelf appeal and influence purchasing decisions. Clear tubes also allow for creative design elements, such as gradient effects or visible shimmer particles, which can differentiate products in a crowded market.

The lip gloss tube industry continues to evolve with new technologies and market demands. Manufacturers are exploring advanced materials that offer improved performance characteristics while maintaining cost-effectiveness. These innovations include smart materials that respond to temperature changes, enhanced barrier properties for product protection, and improved sustainability profiles.

Digital printing technologies are revolutionizing tube decoration, allowing for more complex designs and smaller production runs. This flexibility enables brands to offer limited editions and personalized packaging options, meeting the growing demand for unique and customized products.

Sustainability considerations are driving significant innovation in tube design and manufacturing. Companies are developing mono-material solutions that simplify recycling processes and exploring bio-based alternatives to traditional plastics. These efforts align with global initiatives to reduce plastic waste and improve packaging sustainability.

The empty lip gloss tube market represents a significant segment of the cosmetic packaging industry. Manufacturers must balance cost considerations with quality requirements while meeting increasing demand for sustainable solutions. The economic impact extends beyond direct manufacturing costs to include factors such as transportation efficiency, storage requirements, and end-of-life disposal considerations.

Global supply chain dynamics influence the manufacturing and distribution of empty tubes. Manufacturers must maintain efficient production schedules while adapting to changing market conditions and regulatory requirements. This includes managing raw material costs, labor expenses, and production capacity to meet market demand effectively.

Manufacturing empty lip gloss tubes requires adherence to strict regulatory standards across different markets. These regulations cover material safety, manufacturing processes, and quality control requirements. Manufacturers must maintain current certifications and documentation to ensure compliance with various international standards.

Safety considerations extend beyond basic material requirements to include factors such as child-resistant features, tamper-evident seals, and proper labeling. Manufacturers must also ensure their products meet specific market requirements for different regions while maintaining cost-effectiveness.

The empty lip gloss tube industry exemplifies the intersection of manufacturing excellence, design innovation, and market responsiveness. From squeeze tubes to clear packaging options, manufacturers continue to develop solutions that meet evolving consumer needs while addressing sustainability concerns. The future of this sector will likely see continued innovation in materials, manufacturing processes, and design features as companies strive to create packaging solutions that combine functionality, aesthetics, and environmental responsibility.

As the cosmetics industry continues to grow and evolve, the role of packaging manufacturers becomes increasingly important in delivering solutions that meet both brand requirements and consumer expectations. The ongoing development of new materials, manufacturing techniques, and design innovations ensures that empty lip gloss tubes will continue to play a crucial role in the beauty industry's success while adapting to changing market demands and environmental considerations.